Ever wondered what really goes into our creative process when we design solid wood entry doors?

It's time for us to pull back the curtain--just a little--on how we create and build our most unique designs.

The Zuma diagonal glass wood entry door seemed like a good place to start, because it's one of our production team’s absolute favorites—which I didn’t expect when I asked. Honestly, I thought they'd dislike it, because diagonal elements are more difficult and time-consuming to build. But craftswoman Samantha C. told me, “This is my favorite design that we make.It’s so unique and different from anythingI’ve seen.”Samanthaworks in finishing, so she sets glass in doors, preps the doors for hinges, and does other fine detail work. And Ryan M, who is our millwork lead, says that “in the door world of right angles and straight lines, this one really catches your eye.”

Read on to discover why this design is so esteemed by the artisans who build it.

The Design: Why This Solid Wood Entry Door Design Stands Out

Our CEO Don loves coming up with new door designs. He has a prolific creative drive, and is always seeking to innovate and try new things. Diagonal motifs are an element he likes to incorporate whenever he can, because of how modern they feel. Originally he intended to have this design be an exclusive for custom pivot entry doors.

“This really is a beautiful design," he says. "The diagonal panels end up looking more dramatic on a wider door panel, which we like. But then our clients started to request the design as a standard entry door, so we decided to add the Zuma to that collection."

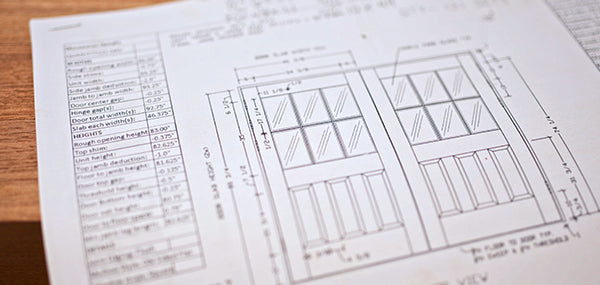

Fortunately, pivot wood entry doors and entry door designs can be interchangeable. While pivot doors are wider than entry doors, all it takes is some simple adjustments to the design's proportions to turn a pivot-first design into a narrower entry door. In this case, the angle of the diagonals is steeper on entry door slabs than on the original pivot door design. Unlike mass-produced options, our solid wood entry doors are built to order, so our drafters continue to adjust the angles of this design to suit each unique door size. Don says, "It’s always surprising to me, even after thirty years in the door business, the directions these designs take. Or what ends up being popular. You never know what's going to really resonate with people. That's why we build the doors no one else will even attempt. The Zuma is one of those.”

Naming A Diagonal Glass Front Door

image credit: Andre Fueh via Unsplash

It’s called the Zuma door because it has a coastal feeling. Sometimes a design name is obvious, but other times it’s just because the design evokes a certain mood or setting. As the creative copywriter at RealCraft, I (Amber) come up with product names. And I named this door Zuma after the famous surf break in Malibu, California because the surf is best there when it's a crossed-up swell. In other words, that's when waves come in diagonally from both north and south thanks to the Santa Ana winds. I grew up surfing in Southern California with my dad, and Zuma is a place he talks about often. Zuma can get treacherous in summer, with notoriously vicious left-breaking waves. But it was also one of my dad's proving grounds as a young surfer when the swell was hitting just right. When I saw the design, it made me think of that place and a massive lineup at the height of summer.

The Challenge: Modern Diagonal Glass Meets Traditional Craftsmanship

Ideation and naming are just the beginning. Our production team also has to verify that new designs are feasible to build. Sometimes, if a design is unusual enough, we create a prototype. As specialists inwood entry doors with glass, we have experience making every kind of design you can think of, so long as it fits within our construction methods. Since we use solid wood and mortise-and-tenon joinery, certain designs—like ones made with a CNC machine—aren't in our wheelhouse.

But many other features are, including diagonal wood and glass panels. When it's time to assess the feasibility of a design, our shop foreman, Ryan Rodman, has the deep expertise that comes with experience. With fifteen years here at RealCraft, he’s assembled thousands of doors in all kinds of designs. “One thing I knew we’d have to do is make the panels full thickness,” he says. A full thickness solid wood panel construction, similar to flush panels, means that the panel is the same thickness as the rails and stiles of the door. Usually with paneled doors, the panel is thinner than the frame.

“Aesthetically, it just wouldn’t look right otherwise with a diagonally oriented panel that has both wood and glass," says Ryan. "It just has to look more premium in that case, and the full thickness panel achieves that. For a wood-only diagonal panel, that’s different. We do that with the Mountain Chevron and Four Panel Chevron doors, the panels are thinner than the frame. Because they can look more rustic. But for the Zuma, just like for the Monarch entry door, the panels have to be full thickness.”

Otherwise, Ryan judged that the construction would be straightforward. So we moved forward with it, built the product page, and set it live.

The Process: Building This Solid Wood Front Entry Door

This solid wood front entry door starts, like all the others, as raw lumber. Our production team selects boards for each door slab one-by-one, looking for grain patterns that suit each specific design. If a door is Black Walnut, they might look for a blonde streak to feature on one of the legs. If a door is Clear Douglas Fir, they choose the boards that are as free of knots as possible. Because each board of lumber is different, and each artisan is different, no two doors of ours will ever look the same. But that’s also what makes them beautiful. They reflect not only the infinite variety of nature, but also the unique tastes of the people who build them.

The lumber is then cut to size and planed to be straight. Depending on the dimensions in which the lumber is sold, and the dimensions of the door, the team may laminate pieces together to reach the desired size.

Next, the panel pieces are cut and assembled. Mortise pockets and tenons are cut from the frame pieces with exacting accuracy and precision. After all, the strength of the joint depends on it. Mortise and tenon joinery is a specialized technique, and an ancient one. It results in a joint that’s much stronger than other joint types.

Once the panel and frame are united, the glass is set in the door. Much of the ‘finishing,’ or fine detail work, is done by hand. So is the application of stains, sealants, and primer.

While any of our wood species would be ideal, this wood entry door looks beautiful as shown in Black Walnut, which you can now see in person in our showroom. Other species we love for this design are Sapele Mahogany, Padauk, and Plain Sawn White Oak. Learn more about choosing a wood species for solid wood entry doors.

Shop the Zuma design for both solid wood entry and premium custom pivot doors.

Christina Miller

October 03, 2025

Thank you, love the Zuma name and how you came up with the idea to be different 😀 😉