When it comes to creating high-quality doors, furniture, and home accents, the way pieces of wood are joined together is just as important as the wood itself. Wood joints are the fundamental connections between the components of any design, determining the strength, durability and quality of the final product.

Here's why it matters for you: understanding the different kinds of joints is essential for any homeowner—or anyone who buys wood products at all—because it can help you decide if something is worth your money or not. Some wood joints are better at certain purposes than others. The right wood joint can mean the difference between a piece that falls apart in a year, and one that becomes a cherished family heirloom.

What is a wood joint?

A wood joint is a method of connecting two or more pieces of wood to create a stronger, more stable structure. There are various joinery techniques, and they all have their own upsides and downsides. Here are some of the features impacted by wood joinery:

- Structural Integrity: Proper joints distribute stress and weight evenly across the wood. Wood expands or contracts in different directions because of the wood grain itself. A proper joint is fitted together with the directional nature of the material in mind.

- Aesthetic Appeal: Different joints can make a door or piece of furniture look more beautiful.

- Durability: The right joint prevents weakening, splitting, and separation over time. This is critical for anything weight bearing, like a table or chairs, or for anything with heavy daily use, like a door or cabinet drawers. The right joint makes any piece more functional as well.

And these are some of the most common types of wood joints--including the wood joint we use most often in our 100% solid wood doors here at RealCraft.

Butt Joint

The simplest and most basic wood joint, where two pieces of wood are joined at their ends or sides. It gets its name from the fact that the pieces “abutt” each other. These joints always have to be reinforced with fasteners or glue, unlike more advanced joints that may not require fasteners. But it’s also the weakest type of joint.

Common Uses: Basic construction, temporary structures, rough carpentry

Biscuit Joint

A biscuit joint uses oval-shaped compressed wood "biscuits" inserted into matching slots to align and strengthen the joint. The biscuits swell once inserted and create a joint without the need for fasteners or glue. A biscuit joint results in a seamless look, one of the reasons why it's so popular. However, it requires a specialized tool to cut the biscuits themselves which can be prohibitively expensive for the hobbyist woodworker.

Common Uses: alignment for edge-to-edge grain gluing and furniture, as well as repairing damaged furniture

Rabbet Joint

A rabbet is a notch cut into the edge of a board to receive the edge of another board. They can run with or across the grain pattern. Our white oak thresholds on our entry doors are joined to the jamb legs with a rabbet joint, as you can see above.

Common Uses: Cabinet backs, drawer bottoms, picture frames

Dovetail Joint

A dovetail joint is one of the best known types of wood joints because of its distinctive look. It’s characterized by trapezoidal-shaped interlocking "tails" and "pins". You’ll see it most commonly in furniture, including cabinet drawers. This type of joint is extremely strong as well as beautiful. Best of all, it doesn’t require additional fasteners. A dovetail joint requires specialized skill and is time-consuming to create. In a time of mass production and ruthless efficiency, dovetail joints have become rarer and rarer. But a dovetail results in both longevity and visual appeal. When you see it in a piece of furniture, it’s a mark of exceptional quality.

Common Uses: Fine furniture, drawers, high-end cabinetry

Mortise and Tenon

Above: mortise pockets

Above: tenons

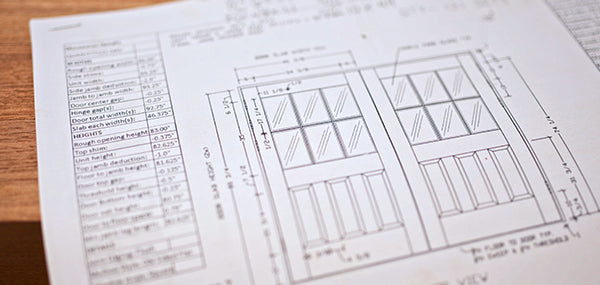

Alongside joints like dovetail (and the related finger joint), mortise and tenon joinery stands out as a mark of quality and fine woodworking. One piece (tenon) is cut to fit precisely into a hole (mortise) in another piece. When used to build doors, this is also called rail-and-stile joinery. The rails are the horizontal framing pieces with the tenons, while the vertical pieces, known as stiles, have the mortise pockets.

This joint type is extremely strong and distributes stress evenly, resulting in unparalleled longevity and durability. It’s also time-consuming to create because it requires flawless precision and high levels of expertise. Like dovetail joints, mortise and tenon joints are a mark of fine quality, often seen in traditional carpentry and heirloom furniture.

A Truly Ancient Tradition: What Makes Mortise and Tenon Joinery Special

Mortise and tenon is the joint type we use for virtually all of our doors, aside from our plank-style barn doors. It’s one of the things that makes our product unique, because most door builders don’t want to deal with the added time, expense, and expertise needed to build this way. And it’s a hidden feature—you can’t usually tell if a door is mortise-and-tenon just by looking at it.

But all the reasons why other people avoid using this joint—the time, precision, and expertise—are why we choose to use it. We use mortise and tenon joinery specifically because it’s traditional.

In fact, the mortise and tenon technique is ancient. It’s one of the oldest known wood joints, having been in use since the Neolithic era, thousands of years ago. Remains of a 7,000 year old wooden well with this kind of joint have been discovered in present-day Germany.

Back then, Neolithic humans had hard lives--most of their time and energy would be spent on finding and preserving food. But even in those days, ancient woodworkers took the time to make and use this kind of joint because they recognized its longevity.

These prehistoric carpenters had fashioned boards and beams from old-growth oak and then fit them together using mortise-and-tenon joints.In a similar vein, the ancient Romans were also known for their use of mortise and tenon joints in their grand palaces and temples--five millennia later.

Even our modern designs, like the Peninsula Pivot Door or Mid Century Modern Side Window door, feature mortise and tenon joints as part of their construction. This is how we blend the best of traditional woodworking with innovative, daring modern designs.

Tongue and Groove Joint

The chevron panel in this Mountain Chevron Entry Door is tongue and groove.

This joint creates an interlocking connection with a protruding "tongue" fitting into a matching "groove". Both the tongue and the groove run the entire length of the board. You’ll commonly see this joint in wall or door paneling, as well as flooring.

We use it on our door panels and offer it in our accent walls. While other joint types accommodate the natural movement of wood, tongue and groove joints prevent wood movement and add stability.

Common uses: flooring, wall paneling, paneling in doors

Leave a comment (all fields required)