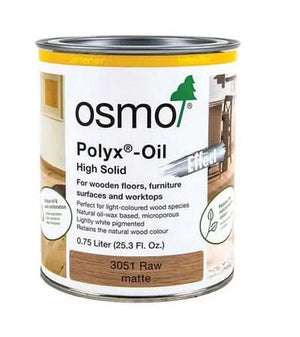

Durable Satin Finish for Interior Wood Surfaces

Osmo Hardwax Oil Polyx Interior Oil Finish offers unmatched durability and elegance for your wood surfaces. The 3043 satin finish is specifically designed to protect interior wood floors, furniture, and paneling, enhancing the natural beauty of the wood while ensuring resistance to everyday wear and spills. Its microporous structure bonds with wood fibers for long-lasting protection that doesn't crack, peel, or flake, and the finish is VOC-compliant and safe for homes with children and pets.

- Approx. Coverage: 258 sq. ft./L per coat

- Number of Coats: 2 coats

- Application Temperature: +5°C to 35°C

- Approx. Dry Time: 8-10 hours

Please note: Osmo Polyx Oil 2.5L cannot be shipped to the following States: CA, MN, WI, IL, MI, OH, PA, NY, VT, NH, ME, UT, AZ. Please see our OTC Complaint Polyx Oil from Osmo for an alternative.