Natural UV Protection For Exterior Wood Surfaces

Osmo UV-Protection-Oil is optimal for all vertical wood surfaces in outdoor areas, including:

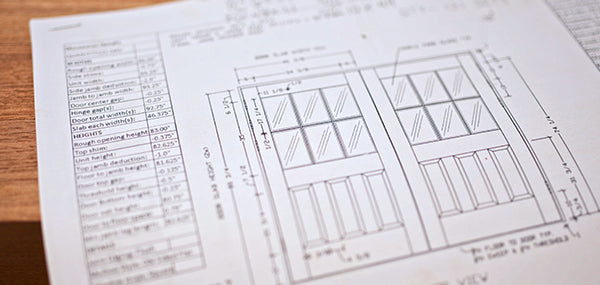

- Doors

- Windows

- Window shutters

- Carports

- Timber cladding

- Balconies

- Fences

- Pergolas

- Gazebos

The UV Protection Oil combines water resistance and biocides for optimal protection from the elements. Unlike urethane-based finishes, it won't peel, crack, or flake, and it minimizes swelling and shrinkage too. As a top coat on already color-treated wood, Osmo UV-Protection-Oil preserves the wood much better and allows you to go longer between finish renovations. Applied on its own, it blocks the greying process on vertical surfaces with a UV protection factor 12 in comparison to untreated wood when two coats are applied. Note: for wood decks, we recommend Decking Oil.

Features and Benefits:

- Clear Natural Oil-based finish with 12x UV-Protection

- Very water and dirt resistant

- Reduces wood swelling and shrinkage

- 420 contains biocides to prevent the growth of algae, mildew, and fungal attack

- No sanding necessary for future applications

- Made in Germany – Conforms to strict German and European norms

Preparation

Ensure that wood surfaces to be treated with Osmo UV Protection Oil are clean, dry and frost-free (moisture content max. 20%).

New Wood

- Surfaces should be sanded with a 120 grit abrasive and no finer

- New wood and especially hardwoods should be allowed to weather for approximately 6 weeks prior to oiling

- De-grease surfaces with methylated spirit or Osmo Brush Cleaner and Thinner (8000) before oiling

- Fill any holes or gaps with an exterior gap sealer

Please Note: Allowing new wood to weather for six weeks, especially dense exotic hardwoods, is our recommendation for best results. This allows the dense grain of the wood to open up. This makes the UV protection wood finish easier to apply, and allows it to penetrate deeper into the wood grain.

Old Wood

Clean old micro-porous finishes (wood oils) thoroughly

- Areas affected by mold, algae and moss must be cleaned and treated

- Old paints, lacquers and varnish like stains must be completely removed

- The color of timber that has turned grey / silver over time can be restored prior to oiling with Osmo Wood Reviver Gel (6609)

- Then treat as New Wood

Application

Always do a test area before starting any project to check suitability and compatibility. Follow the manufacturer’s instructions on the tin at all times.

- Stir thoroughly before and periodically during application

- Where possible treat all sides prior to installation

- Apply protection oil thinly along the wood grain with a natural bristle brush

- Work the oil into the surface of the wood grain

- Wipe of any excess with a clean, lint-free cloth

- Allow to fully dry

- Apply a second coat as above

Aftercare

Regular Cleaning

Oiled surfaces can be regularly cleaned with a suitable exterior spray cleaner that won’t strip away the waxes and oils.

Renovation

When renovation is required, ensure that surfaces are clean and dry.

- Lightly sand or use a stiff brush to remove surface dirt and debris

- Apply a thin maintenance coat of Osmo UV Protection Oil, taking care to work the oil in to the surface of the wood and wiping off any excess

- For wood that has become discolored or is showing signs of mold, algae or moss, refer to the preparation and application sections above